×

Exterior

Anchors & TieDowns

Doors & Windows

Coatings & Sealants

Appliance

Tools & Hardware

Interior Trim

Vents & Registers

Plumbing

Electrical

Transport & Safety

Heating & Cooling

RV Catalog...

RV Catalog...

×

Storm Doors

Combination Doors

Outswing Doors

Other Doors

Door Hardware

Windows

Shutters

Window Components

Skylights

×

Water Heater

Faucets

Faucet Components

Sinks

Tub & Shower

Toilets

Fittings & Valves

Tools & Tubing

Freeze Protection

×

Furnace Illustrations

Furnace Components

Furnace Filters & Doors

Heating & Cooling

A/C

Freeze Protection

×

Outdoor & Accessories

Awnings & Covers

LP Gas & Appliance

Electrical & Electronics

Ventilation

Hardware & Doors

Automotive

Cargo & Tow Cleaners & Sealants Fresh Water Sanitation Jacks & Levelers Suspension & Brakes

Mobile Home Catalog...

Cargo & Tow Cleaners & Sealants Fresh Water Sanitation Jacks & Levelers Suspension & Brakes

Mobile Home Catalog...

←

×

- Refrigerators

- Refrigerator Components

- Water Heaters

- Water Heater Components

- Range/Cooktops

- Range Hoods

- Range Hood Components

- Furnaces

- Furnace Components

- Insect Screens

- Washers & Dryers

- Washer & Dryer Components

- Air Conditioners

- Air Conditioner Components

- Appliance Illustrations:

- Water Heater Diagrams

- Furnace Diagrams

- Refrigerator Diagrams

- EXTERIOR

PARTSSkirting

Exterior

Steps

Lawn & Garden

- ANCHOR &

TIE DOWN - DOORS &

WINDOWS - COATING &

SEALANTCoatings & Sealants

- APPLIANCE

PARTSAppliance Assessories

- TOOLS &

HARDWARE - INTERIOR

TRIM - VENTS &

REGISTERSRegisters/Vents & Grilles

Roof & Plumbing

Kitchen & Bath

- PLUMBING

PARTSWater Heater

Tub & ShowerSinks

Toilets

Tools & TubingFaucets

Faucet ComponentsFittings & Valves

- ABS (Drain Pipe)

- PVC (Drain Pipe)

- Qest

- Push-Fit

- Flair-It

- PexLock

- PEX Barb (Brass)

- PEX Barb (Plastic)

- Rubber Couplings

- Valves

Freeze Protection - ELECTRICAL

PARTSSwitches & Outlets

Power Supply

Freeze Protection

- TRANSPORT

& SAFETY - HEATING

& COOLINGFurnace Illustrations

Furnace Filters & DoorsFurnace Parts

Heating & Cooling

- RV/CAMPER

PARTS →

- ← MOBILE

HOME PARTS - OUTDOOR &

ACCESSORIES - AWNINGS

& COVERS - LP GAS &

APPLIANCELP Gas

Appliance

Appliance Parts

Illustrations - ELECTRICAL &

ELECTRONICSElectrical

Electronics

Lighting

- VENTS &

REGISTERS - HARDWARE

& DOORSHardware

Door & Window

Tools

Steps & Ladders

- AUTOMOTIVE

CARGO & TOWAutomotive

Carriers & Haulers

- CLEANERS

& SEALANTS - FRESH WTR

PLUMBINGFresh Water

Faucets

Faucet ComponentsFittings & Valves

- PEX Barb (Brass)

- PEX Barb (Plastic)

- Qest Fittings

- Push-Fit Fittings

- Flair-it Fittings

- Pexlock Fittings

- Rubber Couplings

Freeze Protection - SANITATION

PLUMBING - JACKS &

LEVELERSJacks, Couplers Levelers

- SUSPENSION

& BRAKESAxle & Suspension

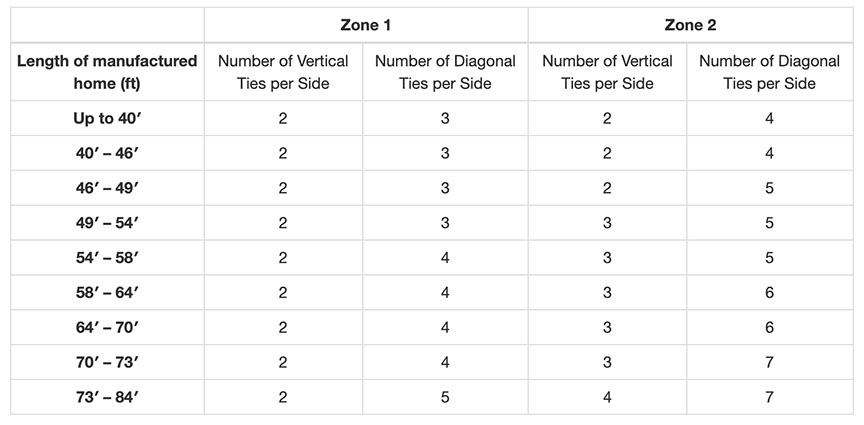

When strong winds blow, manufactured homes need special protection. No matter where you live, you need tie-downs and anchors to keep your manufactured home stable and secure. Before you start the job, you should understand why this wind protection system is necessary, and know the basic requirements for tie-downs and anchors. You also need to become familiar with all the components that make up your anchoring system. It's a good idea to consult with an experienced professional installer or building inspector if you have any questions or doubts about the installation.

When strong winds blow, manufactured homes need special protection. No matter where you live, you need tie-downs and anchors to keep your manufactured home stable and secure. Before you start the job, you should understand why this wind protection system is necessary, and know the basic requirements for tie-downs and anchors. You also need to become familiar with all the components that make up your anchoring system. It's a good idea to consult with an experienced professional installer or building inspector if you have any questions or doubts about the installation.